Jumping Robot "Z-hopper"

Project developer: Serguey Lonchakov, 4th year student, and Serguey Azarkin, 3rd year student

Scientific supervisor: Serguey Zapunidi

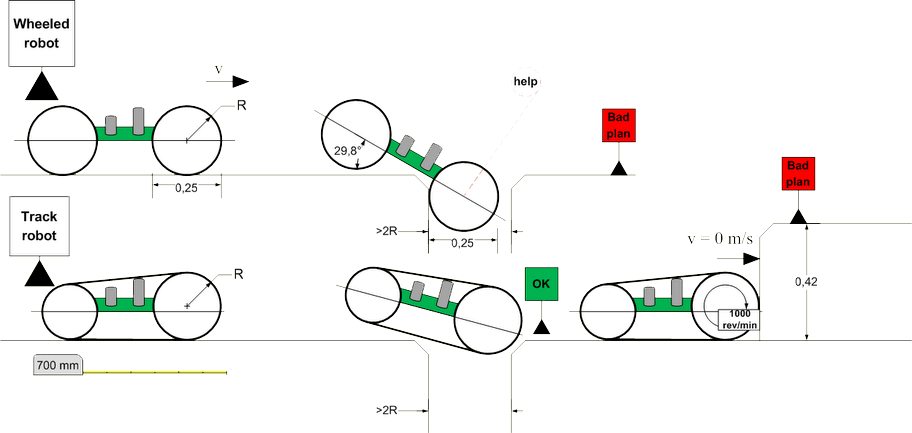

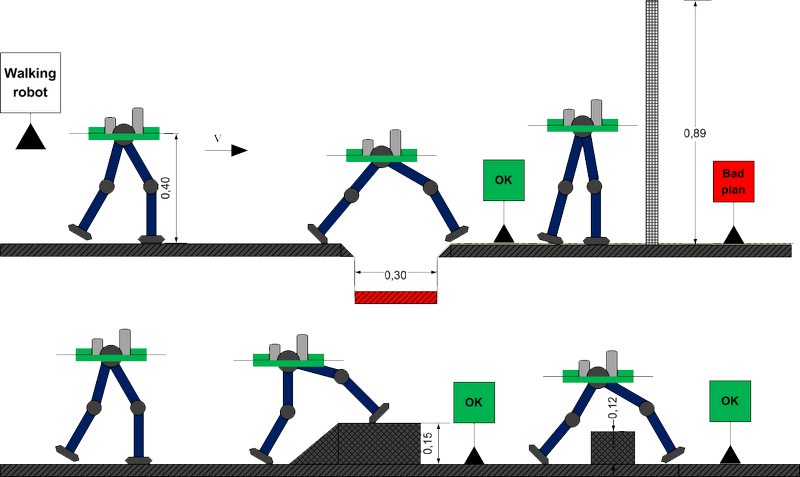

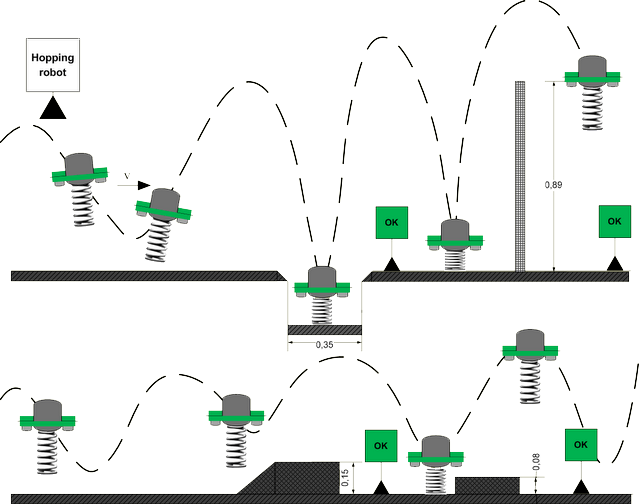

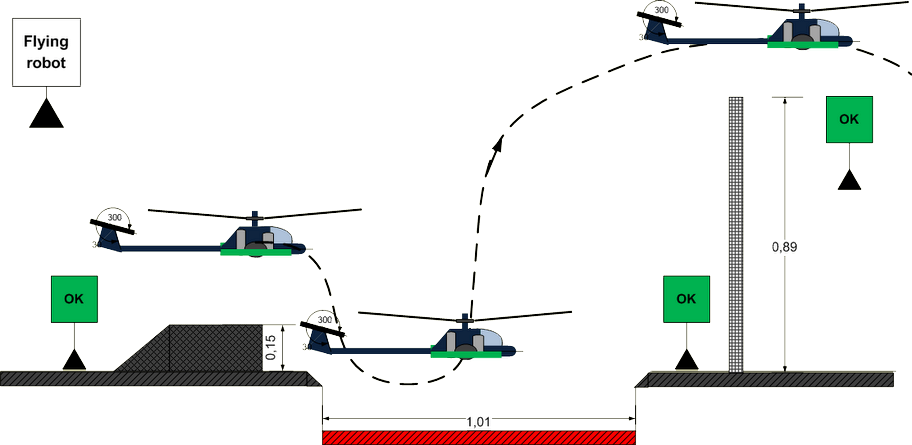

The project is working on creating a robot-platform which performs hopping movement, an absolutely new principle of movement for automatons. The whole idea of hopping movement is not entirely new; it is well known even to children as a Pogostick or a Flybar. However, if for an adult walking, running, jumping or climbing do not seem to cause any problem, but two-legged robots have just caught up with average speed of a human being, and that is after 20 years of work. Movement is often possible on flat surface only (see leading world achievements PETMAN (Boston dynamics, USA), HRP series (AIST, Japan), Humanoid (Toyota, Japan), ASIMO (Honda, Japan)). There’s a problem of bearing instability on both legs. A robot requires a wide range of sensors and complex algorithms of position stabilization in order to keep calculations on stable position of the legs when walking on uneven surface. Increasing the number of legs partially solves the problem of stability by way of complicating algorithms and decreasing the speed of movement. Wheel and caterpillar bearing is often used but, yet again, it only suits flat surfaces and a simple border stone can become quite an obstacle for a small robot.

Hopping mechanism of movement is insensitive to the form of the surface. It is enough if we have firm surface such as asphalt or dry land. Any obstacle that is lower than an average jump height can be easily overcome. We have to note that the USA finances a similar project Precision Urban Hopper, hopping spy-robot. It moves primarily on wheels and performs single hops in order to overcome a fence. That means that it needs to restore its stability after landing. So why would you implement two movement mechanisms if one is more than enough?

Z-Hopper, the story

My name is Serguey Zapunidi, and I am the leader of Z-Hopper project.

All this began when I was at school and I got interested in electronics and programming. Later on, being a student and then in graduate school of MSU I continued learning about these spheres and by the end of the graduate school I started teaching programming at MSU. I have been teaching a course on 32-bit microcontrollers since 2008, and this course has given me a chance to develop interesting scientific and technical ideas, some of which belong to our students.

2010

The idea of a hopping robot came to me in 2010, and it seemed rather impossible in the beginning because its implementation required costly sensors, special mechanical centers, and complex algorithms. Step-by-step I came up with the solutions to the basic problems of the short-term and long-term stabilization, movement, navigation and energy booster. This idea seemed to be shaping up and gradually became possible in the course of our microcontroller classes.

2011

In the beginning of 2011 I offered Aleksey Sizov and Artur Mannanov, two of my students who had already taken the microcontroller course, to work on this project.

Together we developed and made an electronic circuit with microcontrollers, sensors, Wi-Fi, and lots of other useful elements. We also tested the crucial components of the circuit, wrote a skeleton of the firmware, and bought the right springs, which turned out to be a rather difficult task. Despite the amount of the accomplished work, we still had a very long way to go. At this stage we collaborated with Arseniy Gagikurbanov who wrote a part of the scanning code, and he also explained to us why some of the our sensors had been a bad choice. All in all, the work was slow.

We tried taking part in the competition at kulibin.org, but one needs to offer a clearly commercialized product for such a competition, while our project had more to do with military or space technology. As a result, we didn’t find a sponsor interested in the development of the military robots like those of DARPA in the US.

2012

In 2012 our team welcomed Serguey Lonchakov and Igor Balan, students who at that time were taking the microcontroller course.

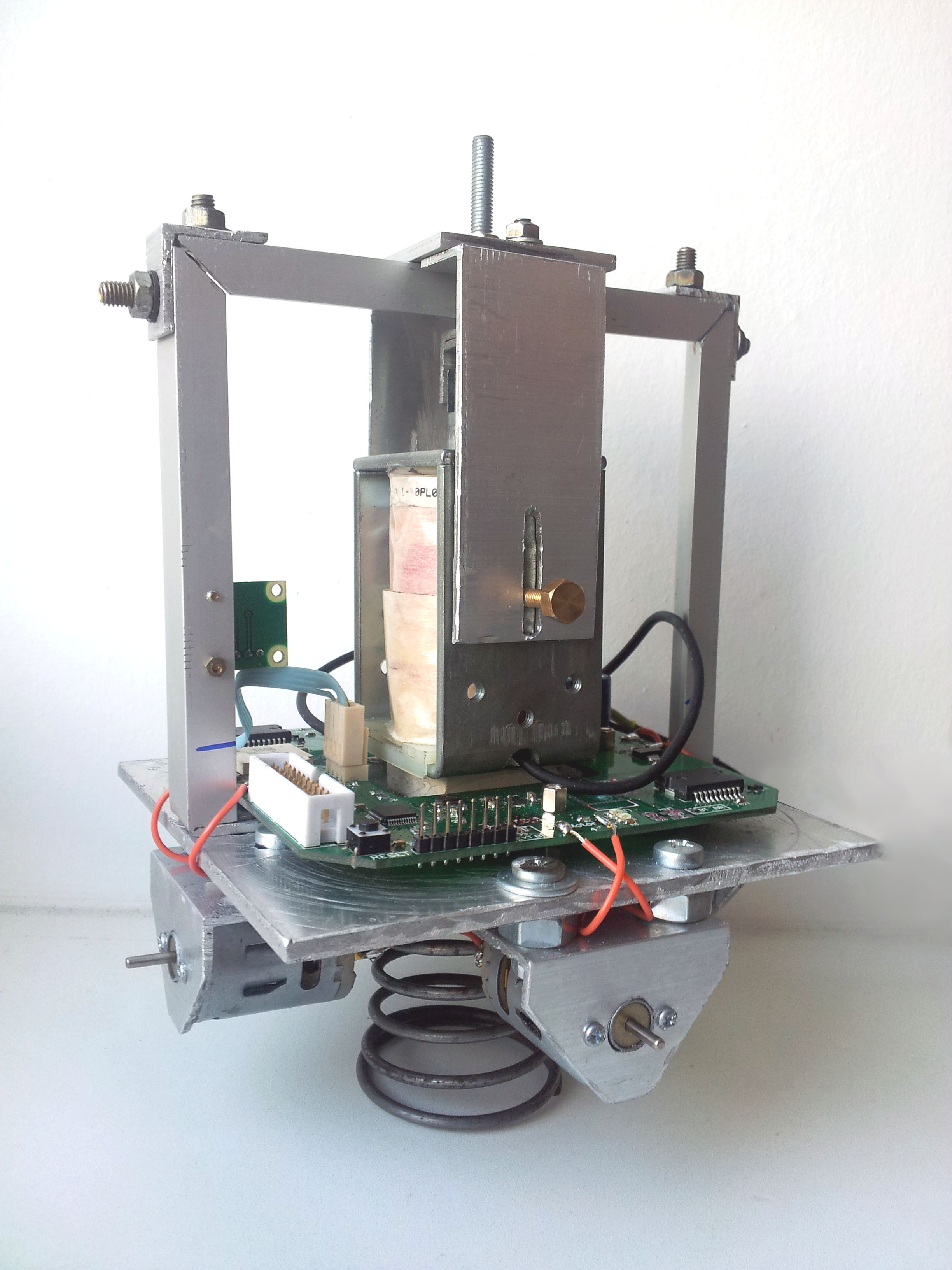

We had a finished board which required more work and some changes, however we didn’t have the mechanical basis. In the period from February till May Igor Balan made the first version the mechanical basis with a mobile solenoid, motors, changeable spring leg, and accumulators. This system had everything but it still couldn’t hop. One of the reasons was that motors required disc plates on the axis, which would increase rotor inertia. Apart from that a spring leg couldn’t provide a substantial stroke without side bending. Nevertheless, at this stage we had something solid and free-standing.

Serguey Lonchakov quickly got the idea of the code we had and then wrote numerous stabilization algorithms, which were still useless at that stage of work. He also managed to find the flaws in the wiring, which caused the loss of connection with the sensors when the motors were rotating rapidly due to electromagnetic cross talks. It became clear how we could modify the board. By the end of May Serguey had managed to launch the algorithm of hop start, which could be achieved by lowering gravitation and implementing artificial stabilization of the Z-Hopper with the help of the balance mass. And the robot started hopping.

In autumn Serguey Lonchakov continues his work on robot but the progress was slow and little was done. It was obvious that we needed a different spring leg, and we also required disc plates for the motor axes for stabilization. It was time to learn how we could actually make parts for the robot.

2013

It was quite clear to me that sheer enthusiasm was not enough to create the first high-hopping system in the world, which was my initial goal. People came and went, there had been many people interested in the project but it demanded total immersion. The things got better when the Engineering Laboratory opened a graduate residency program for students. In 2013 Serguey Lonchakov entered this program, and I was appointed his scientific supervisor. The robot itself couldn’t be the goal of a scientific work but such aspects as hop-start and stabilization mechanisms are presented in the papers published by the IEEE community and even in Phys. Rev. Lett. The latest publication belongs to American group, which designed Precision Urban Hopper. That is why we started working on the scientific side analyzing, calculating, and conducting simulations before any actual production. The work seemed to move faster.

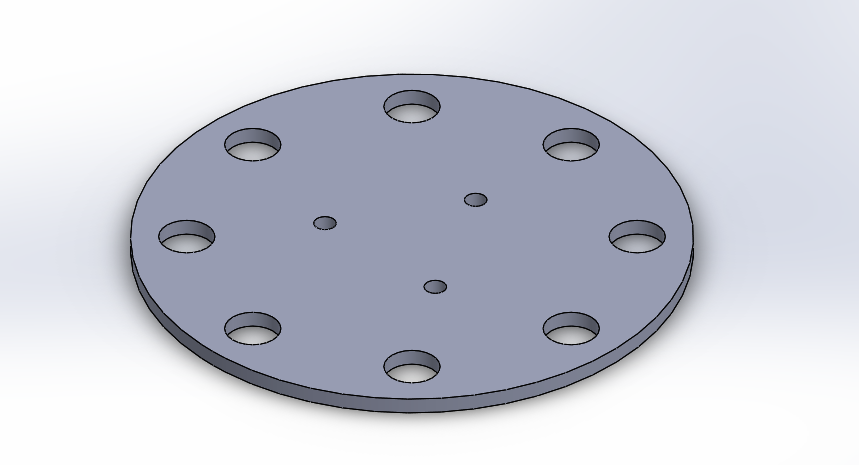

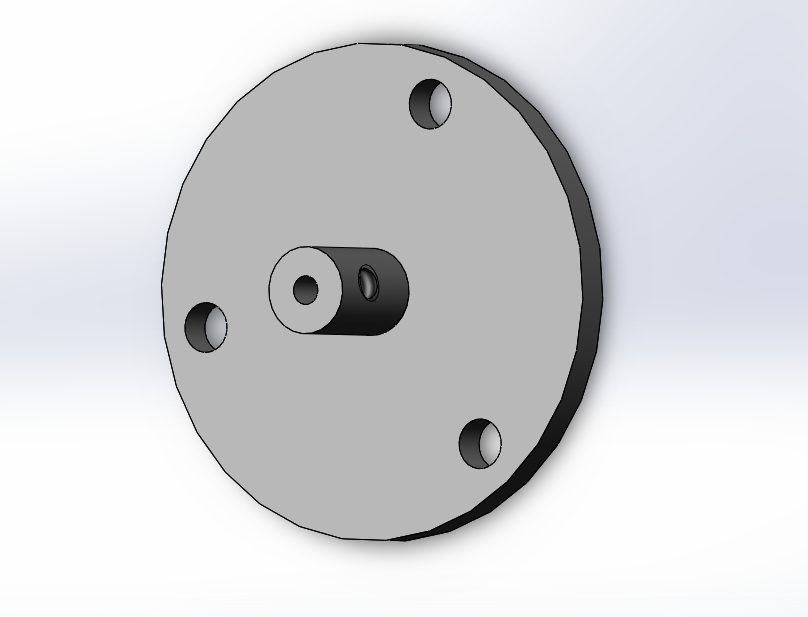

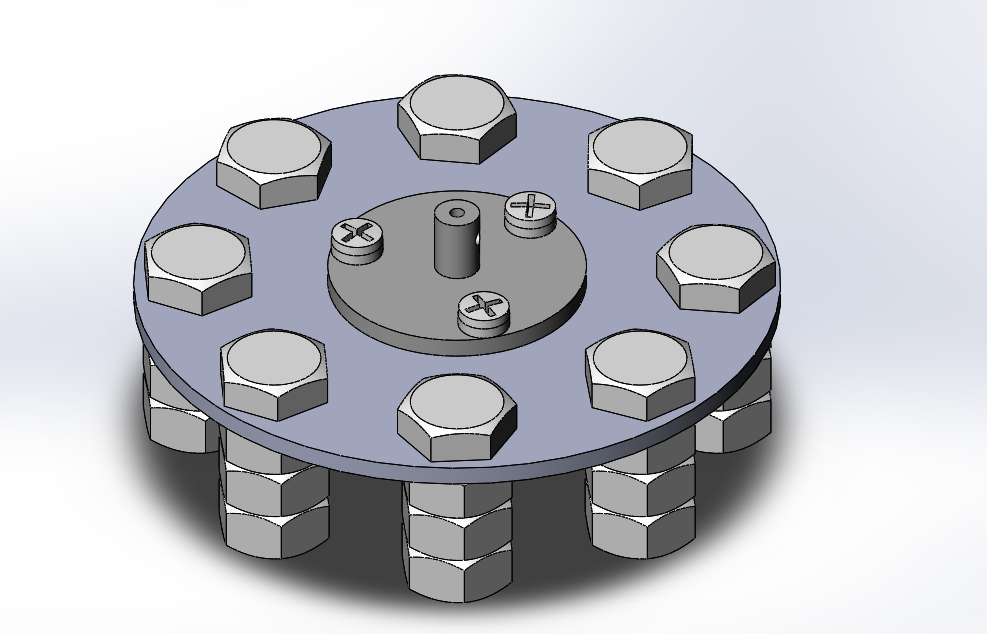

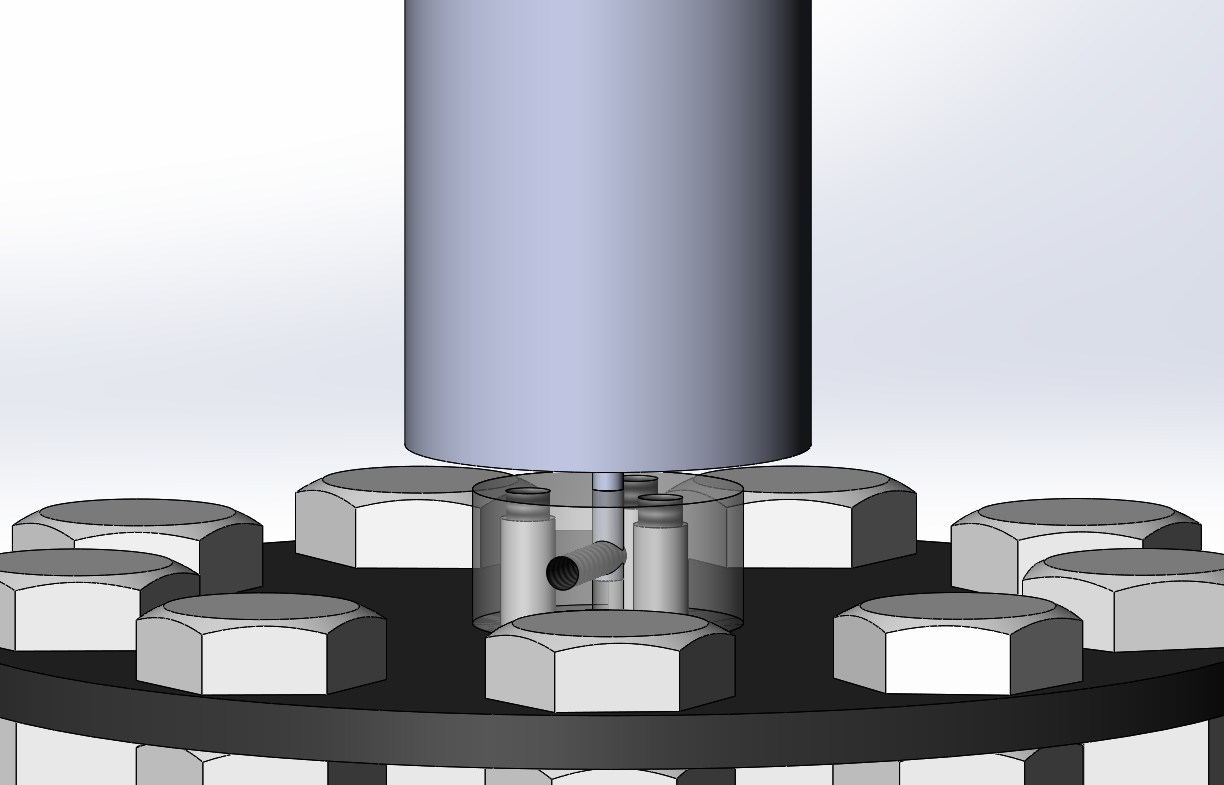

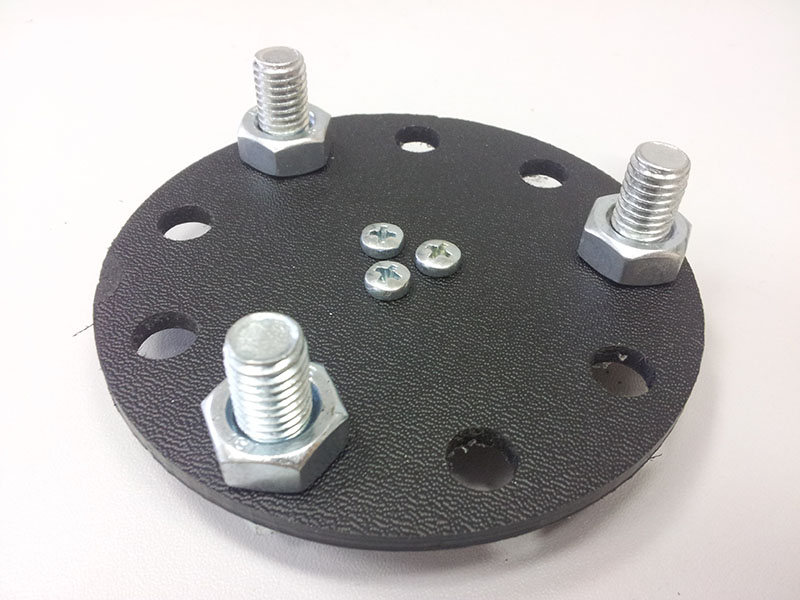

First of all, we discovered modeling in Simulink. It took us almost half a year to learn our way around it and that is why this period had no significant advances. In the end of May Ivan Maksimov and Serguey Shirobokov, who at that time were taking a Microcontroller Programming course, designed simulation of a one-dimensional stabilization of orientation through plate rotation. We also had motor plates ordered and made, and the students attached to motors and tried running stabilization in the real system. Serguey Lonchakov and I beat the cross talks caused by the rotation of the motors, and we managed to accomplish that on the board we had without rewiring. One could even say that we refined the board with the help of a simple file. In June we had new disc plates that turned out to be much cheaper than the first ones.

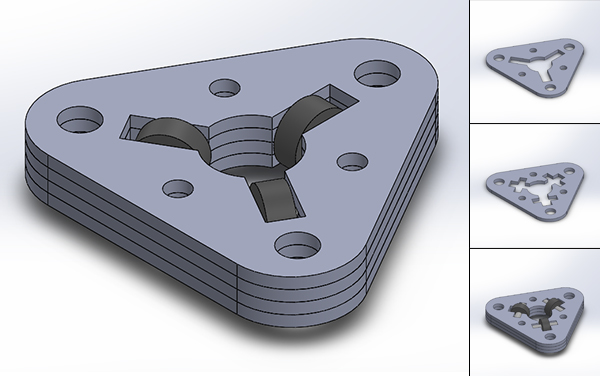

The colossal amount of work we covered in July allowed us to get the right springing leg made. The construction now was a carboniferous leg functioning on one axis on six bearings. These bearings are fixed into triangle holders that are manufactured by laser beam cutting.

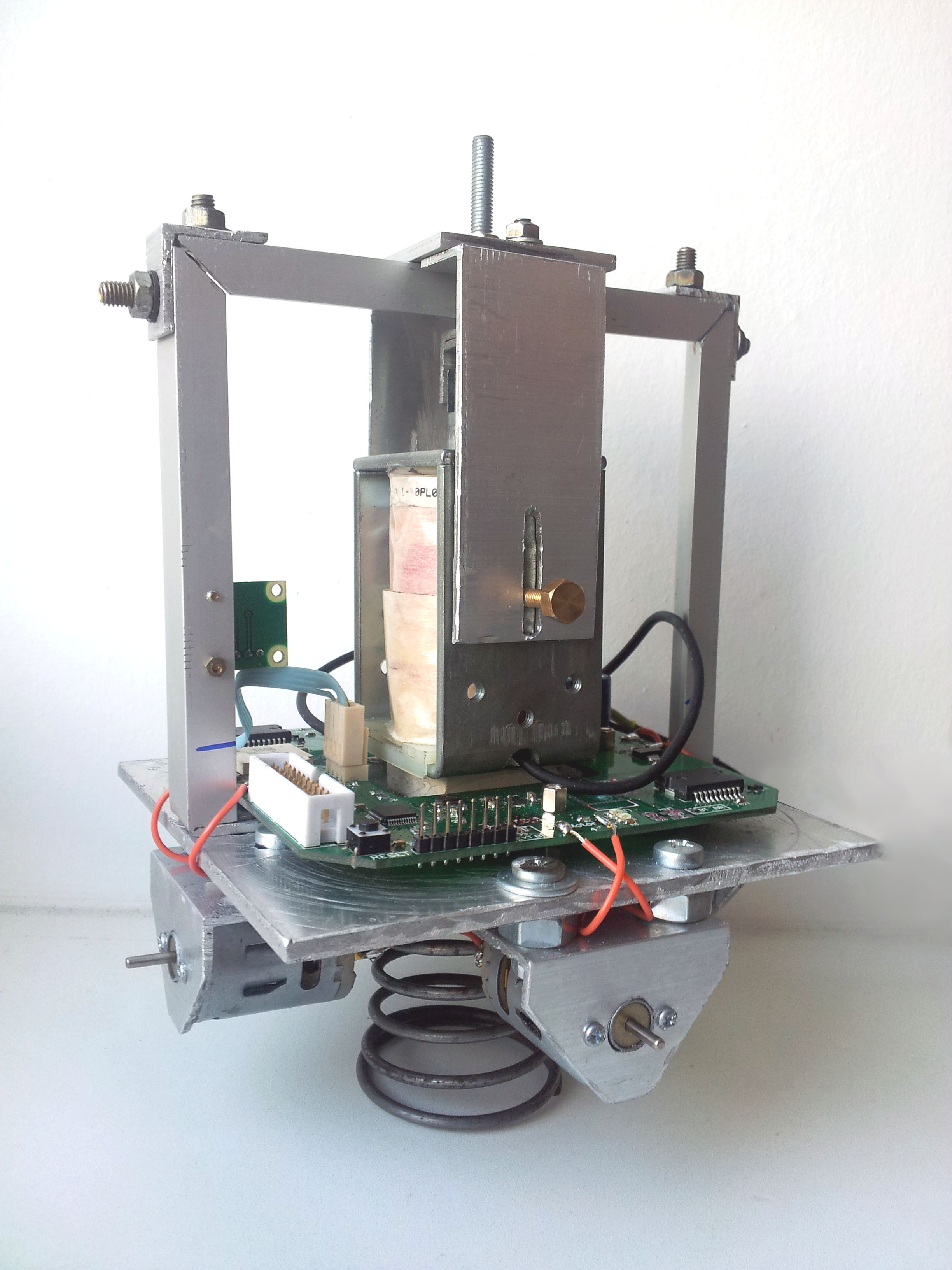

As a result we got this robot:

The system lacked the springs for accumulating energy for hopping. These springs were added in September, and then the robot started hopping.

The stabilization system was also ready from the mechanical point of view. The first goal I set was to stabilize the initials hops without long-term stabilization or boosting energy of a hop. For this purpose we measured inertia of our Z-Hopper and the moment of force developed by the plugged engines. The problems we faced were connected with the engines, as their moment of force was too little to stabilize occasional fluctuations of angular speed at springback. Engines installed on a Z-Hopper prototype were the ones we could get at a regular retail store. They had to be further replaced by special engines with high angular moment that one could only get abroad. New engines with well-known characteristic require changes to the control circuit. Before getting to the next version of a prototype we also had to check the system in simulation.

In September 2013 Serguey Azarkin, one more senior year student, joined the project as a part of his final paper research.

His field is the system of hop initiation while Serguey Lonchakov is working on the stabilization of the position.

To be continued...

Description of the project

We are implementing a revolutionary new mechanism of robotic movement by constant hopping with kinetic energy accumulation during the incidence in an elastic body (spring). Instead of using a bearing part on several wheels or legs we opted for one tangent point. Therefore in order to gain stability it should suffice to point down the tangent point of the platform, and to deviate at a controlled angle for movement. Besides the simplicity of the approach towards movement we get an opportunity to overcome obstacles like walls simply by jumping over them. Consequently, hopping movement comes close to rotor-wing air vehicles in overcoming obstacles, in manoeuvre capability and in the traveling speed while the former maintains low energy input and low noise intensity that are typical of ground robots.

Wheel (caterpillar)

Low flotation. It requires flat surface.

Walking

| Crossing holes and overcoming obstacles of relatively low height. |

| Jumping |

| Overcoming obstacles which excels manifold the height of the robot. Movement on uneven surfaces. |

| Flying |

High-energy consumption. Weight limit on payload. Noise and created wind during the flight.

You can find the dynamic model of the hopping robot here.

Implementation of this project became possible due to the recent progress in the field micromechanical sensors of acceleration and angular speed as well as their entry into the consumer market. Electronic basis of a robot-platform is commercially available sensors and 32-bit microcontroller of ARM family. The system of robot’s orientation and its hop energy boost are executed on modern high-power drivers, while wireless control is implemented on standard digital interfaces: Bluetooth and ZigBee. Modern and commercially available elements make it possible decreasing the cost of the project.

The platform we are working on is the moving base of the robot. It includes everything we need for the integration with the arbitrary functional part: interface of the control of movement, universal radio channel, and the system of the autonomous battery supply. In order to make a finite autonomous robot the platform should be supplemented by a necessary functional block controlling movement.

The main advantage of the project is that we apply the principle of movement for the first time, and that will allow us to find a niche on the developing market of automatons.

The construction of the prototype consists of the start-hop block, the main board (a microcontroller), stabilization block and replacement ‘Leg’ block.

You can download the presentation of this project here.